| Author |

Topic Topic  |

|

B112

USA

5257 Posts |

|

|

skunkhome

USA

12829 Posts |

Posted - 05/16/2009 : 19:21:26 Posted - 05/16/2009 : 19:21:26

|

| that is incredible! I'd bet it costs about $100 per lb. |

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

|

|

|

Roy

USA

1366 Posts |

Posted - 05/16/2009 : 20:15:59 Posted - 05/16/2009 : 20:15:59

|

It is expensive but not quite $100 a pound.

Think Harbor Freight carries the aluminum repair rods. |

Roy

|

|

|

|

B112

USA

5257 Posts |

Posted - 05/16/2009 : 20:51:33 Posted - 05/16/2009 : 20:51:33

|

| I just bought $65 for one pound... $80 with shipping... did I get dupped? Will it work for me? |

Michael |

|

|

|

skunkhome

USA

12829 Posts |

Posted - 05/17/2009 : 00:53:28 Posted - 05/17/2009 : 00:53:28

|

quote:

Originally posted by B112

I just bought $65 for one pound... $80 with shipping... did I get dupped? Will it work for me?

I don't know but if it works it is worth the money I am sure.

be sure you purge the fuel tank before attempting to mend. Lots of folks pump their tanks full of exhaust gases of or dry ice chips to prevent explosion. |

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

Edited by - skunkhome on 05/17/2009 09:56:35 |

|

|

|

B112

USA

5257 Posts |

Posted - 05/17/2009 : 05:36:40 Posted - 05/17/2009 : 05:36:40

|

quote:

be sure you purge the fuel tank before attempting to mend. Lots of folks pump their tanks full of exhaust gases of dry ice to prevent explosion.

Thank you for the tip, searching the web a little harder in that area now. I was planning on having the tank empty, but these gas solutions sound interesting. One person talked about argon gas. |

Michael |

|

|

|

skunkhome

USA

12829 Posts |

Posted - 05/17/2009 : 09:44:01 Posted - 05/17/2009 : 09:44:01

|

Michael, I am sorry I meant to write: "Be sure you purge the fuel tank before attempting to mend. Lots of folks pump their tanks full of exhaust gases of or dry ice chips to prevent explosion."

When I used to be in the freight business, one of the requirements on shipping used machinery was that the tanks be mty and wicked. You may want to do that for a period of time before proceeding. Just a thought.

|

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

Edited by - skunkhome on 05/17/2009 09:57:11 |

|

|

|

BRAD1975

Canada

1562 Posts |

|

|

B112

USA

5257 Posts |

Posted - 05/22/2009 : 02:07:15 Posted - 05/22/2009 : 02:07:15

|

A little update.

quote:

Originally posted by BRAD1975

$65 was the best price I saw too

Yes, that is the same place I ordered it from and it totaled $80 with shipping. My friend told me that it's also available in home depot under a different name. He's leaning towards us using HTS2000 to fix our gas tanks because they include a better presentation and we got it already. Again, Roy thanks for the tip regarding Harbor Freight and Phil, thanks for making sure I read up on how to evacuate the tank of gas fumes. My friend was already planning on welding his tanks and knew he needed to vent the tanks and I'm piggy backing on his repair process. After me finding the HTS2000 we're going with that over welding aluminum. I am also preferring to only braze my tank because the damage is so minor I don't want to chance making a hole if we tried to weld. So it all seems to be working out.

Though, I am getting the recommendation from marine shops and other serious boaters that they'd just go the $1400 buy a new tank route. Ouch. I'm leaning towards fixing this right and not spending that kind of money!

So what does this have to do with tractors? I think it's just one other skill we need in our repairs... I'll update this with some results later. |

Michael |

|

|

|

skunkhome

USA

12829 Posts |

Posted - 05/22/2009 : 07:41:04 Posted - 05/22/2009 : 07:41:04

|

"

So what does this have to do with tractors? I think it's just one other skill we need in our repairs... I'll update this with some results later."

Well you could possibly use it to repair the threads in the spark plug hole...ah, maybe not. |

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

|

|

|

BRAD1975

Canada

1562 Posts |

Posted - 05/24/2009 : 00:25:55 Posted - 05/24/2009 : 00:25:55

|

quote:

Originally posted by B112

So what does this have to do with tractors?

welding up aluminum ramps for getting them in trucks and trailers |

|

|

|

Leroy

USA

413 Posts |

Posted - 06/01/2009 : 21:20:44 Posted - 06/01/2009 : 21:20:44

|

quote:

Originally posted by B112

Anyone ever hear of HTS-2000 or use it? I am planning on using it for an aluminum gas tank repair.

HTS-2000 Aluminum repair:

http://www.youtube.com/watch?v=N-cv3R4fWZc

Micheal I recon the stuff aught to work if the conditions are good.

That video shows the best possible conditions. Unsoiled aluminum without crimped or rolled edges. The primary thing in joining aluminum is cleanliness.

The nice thing about an aluminum fuel tank is you won't cause a spark by running a file over it to removed the oxide prior to welding.

I would put a gallon of lacquer thinner in the tank and shake it a bit then pour it out. We Are not talking $1,400 for a lawn mower gas tank?

Once dry, use warm soapy water to take the thinner smell out of it.

It is the empty tanks that blow up.

With no fuel residue, it won't blow up.

I don't know what your tank looks like but I would think welding up a new one may be a good possibility if your attempt to seal this one doesn't pan out.

Thin folded and wrapped aluminum edges may create a tail you may have to chase.

Lap joints will repair easily after the oxide is removed.

Aluminum oxide is clear and it takes 3 times as much heat to melt it than it does aluminum.

Meaning, if the oxide is not removed, long before your depositing weld metal, the aluminum has sunk to a useless blob.

Can you post a picture of your tank and the location of the leak?

is the leak a crack or a pin hole?

|

Edited by - Leroy on 06/01/2009 21:26:46 |

|

|

|

Leroy

USA

413 Posts |

Posted - 06/01/2009 : 21:57:55 Posted - 06/01/2009 : 21:57:55

|

quote:

Originally posted by B112

A little update.

quote:

Originally posted by BRAD1975

$65 was the best price I saw too

Yes, that is the same place I ordered it from and it totaled $80 with shipping. My friend told me that it's also available in home depot under a different name. He's leaning towards us using HTS2000 to fix our gas tanks because they include a better presentation and we got it already. Again, Roy thanks for the tip regarding Harbor Freight and Phil, thanks for making sure I read up on how to evacuate the tank of gas fumes. My friend was already planning on welding his tanks and knew he needed to vent the tanks and I'm piggy backing on his repair process. After me finding the HTS2000 we're going with that over welding aluminum. I am also preferring to only braze my tank because the damage is so minor I don't want to chance making a hole if we tried to weld. So it all seems to be working out.

Though, I am getting the recommendation from marine shops and other serious boaters that they'd just go the $1400 buy a new tank route. Ouch. I'm leaning towards fixing this right and not spending that kind of money!

So what does this have to do with tractors? I think it's just one other skill we need in our repairs... I'll update this with some results later.

Michael if you look again at that video they are joining two thick chunks of aluminum after filing and wetting.

Your tank is not that thick. The oxiacet flame is a welding flame, capable of ruining your fuel tank if it is held in one spot long enough.

I did not see in the video weather they were using a carburizing, neutral, or oxidizing flame. It will make a difference.

I'm thinking it should be a neutral flame.

My advice, is to go to your community college. Ask the welding instructor if he knows someone who can weld aluminum.

If you don't want to risk $1400.00.

|

|

|

|

Leroy

USA

413 Posts |

Posted - 06/01/2009 : 22:03:44 Posted - 06/01/2009 : 22:03:44

|

| If the tank is removable a tig welder can fix it. |

|

|

|

B112

USA

5257 Posts |

Posted - 06/02/2009 : 06:51:53 Posted - 06/02/2009 : 06:51:53

|

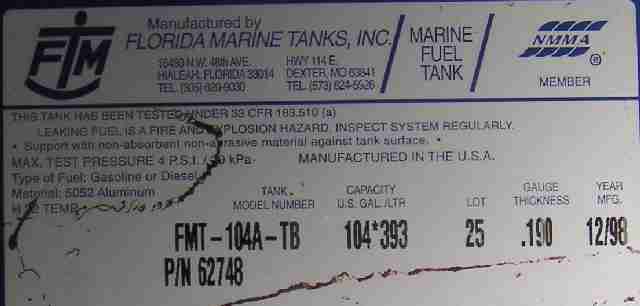

Leroy thanks for the input! I'll need to get a picture of the small start of a hole, one one very bad spot, no leaks, but three places that I'd repair before replacing the tank back in the boat. I need to pressure test it also. The label says tested with 4 psi? Pictures below.

I'm actually getting an exact quote on a replacement tank and calling a tank repair place to get information. Heck if any are the right $$, I'll take the easier route. It's a gas tank for my boat. I've been working on this for a year/off and on. Actually, each time I think I'm getting closer to being able to reassemble it, something else needed to be taken apart! My friend has been explaining me the in's and out's of boat "snowballing". I think tractors have a smaller similar issue, but usually I can put a little spit and glue on the problem and finish my lawn. (Like the steel wire I rigged up to take up some slop in my mid-pto latch lever.)

Anyway, you're comments will all be read along with other research and I'll post my results. I like the laquer thinner idea, someone suggested water? In a fuel tank? I've been venting this for a few weeks, but must get more serious as I have a fuel smell still.

This is the maker of the tank:

http://www.floridamarinetanks.com/ContactUs.cfm

I sent them an email.

Here's a place which makes tanks:

(REMOVED because they are a Marine Industry Thief)

(Notice they use 5052 aluminum, same as on the label.)

This is the label on the tank:

This is the tank (dirty still, cleaned up now):

(left my reserve set of tractor tires in the picture  ) )

This is the rotted bulkhead which separated the engine compartment from the gas tank: (led me to look over the tank)

This is the template to create a new plastic bulkhead:

This is the bulkhead removed from the boat in two pieces being reassembled with the template to route out a replacement plastic bulkhead:

(BTW: I'll post my lawn deck I am cleaning up in another post as I am still working on tractor projects! Reminder, change you're oils and lube your machines if you haven't!) |

Michael |

|

|

|

B112

USA

5257 Posts |

Posted - 06/02/2009 : 07:08:23 Posted - 06/02/2009 : 07:08:23

|

We can change that quote to $1196 and they don't recommend repairing it because "once corrosion has started there is no stopping it." I need to get a second or third opinion here as the defect is small and not leaking yet. Also don't like to hear the "performance limit". I wrote them back about that.

A fuel tank with the provided specifications would be 104 gallons and weigh 147.75 lbs. The tank will be manufactured from .1875 aluminum at a cost of $1196.00 each.

· Tank is manufactured out of 5052-H32 Aluminum Alloy.

· Terms are payment in full to issue drawings and initiate manufacture.

· Lead-time: 3-4 weeks after we receive full payment and drawing approval

· Tanks are quoted FOB Henderson, NC.

· Shipping is not included nor estimated by FMT. Tanks are shipped freight collect.

· This quote is based exclusively on the information contained on drawings. Revisions and/or variations from this information may invalidate this quote.

· Tanks are quoted with pickup (NPTF fitting welded), fill, vent, and electric sending unit.

· We no longer stock or purchase Wema or Rochester Twin-Site senders (visual gauges).

· To ensure the structural integrity and safety of our product, F.M.T. requires mounting information (via drawing, video, and/or written explanation). F.M.T. engineering will assist in advising acceptable mounting modes should you require it.

· FMT recommends tank to have a fully supported bottom with ¼” neoprene rubber strips separating tank with support, and tank to be strapped or bracketed down.

· Tank is not designed for high performance use (application 55 MPH or greater)

· Quote valid for 30 days.

|

Michael |

|

|

Topic Topic  |

|