| Author |

Topic Topic  |

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/22/2011 : 06:33:49 Posted - 12/22/2011 : 06:33:49

|

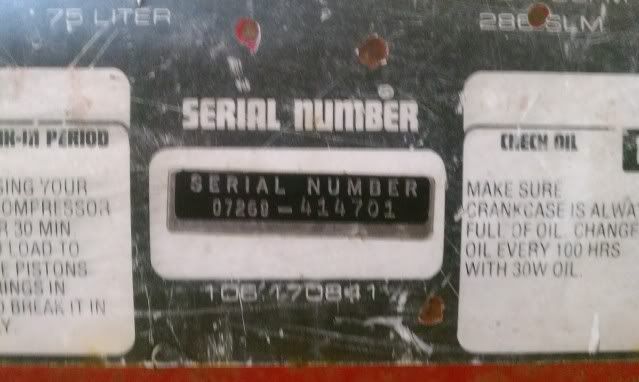

I've used compressors of all types over the years, but never really paid attention to what any of them were. When we moved in, a housewarming/bday gift was an oilless 17 gallon Craftsman compressor. It's done fine for light stuff, and will give great service rotating tires, or cracking a rusted bolt etc. When it comes to running a cutoff tool or die grinder, it runs continuously and canot keep up.

I want to tinker with my own small painting and blasting setup...but compressor prices are steep. Low and behold, by buddy had an old one of his grandfather's he wanted out of the garage. It doesn't work so he said, and for free, I figured I couldn't lose. Turns out, he simply doesn't have an outlet for it. Neither do I.

What are your thoughts on this old girl? I'm going to test it out off my genny, and then run 220 to the garage, which I'd like to have for a welder anyway. I know nothin bout compressors...yet. Hoping it works and don't leak.

|

|

|

|

olcowhand

USA

5115 Posts |

Posted - 12/22/2011 : 09:36:25 Posted - 12/22/2011 : 09:36:25

|

| For painting & light air tool use, this one will do fine. But for blasting parts, it will only be good for small parts unless you like standing waiting for it to catch up. This compressor is no more than 60% duty cycle, so work 6 minutes....wait 4. |

Daniel in Ky -- So much to do, so little time!

|

|

|

|

B112

USA

5257 Posts |

Posted - 12/22/2011 : 10:04:38 Posted - 12/22/2011 : 10:04:38

|

| My sand blaster tells me he uses a screw drive type of compressor. These are big or tow behind units. Lots of air. I have my garage setup with two work spots and have it piped/hosed between the two points. Easier to run a hose in the ceiling than to black pipe it. I too need a bigger compressor. |

Michael |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/22/2011 : 10:20:01 Posted - 12/22/2011 : 10:20:01

|

Hmmm...I'm hearing what you're saying. How does a fella determine that when looking at machines? I'm going to have to do some googling for research. I don't know what all the measures indicate, and what I might even need. Is the cycle limited by the motor or the compressor itself (pump, tank)? I looked at motors, out of curiosity, and those puppies can be expensive.

I'm not a fan of the oil less compressors...the woodshop went through a couple a year at my old job. I have no idea why they continued to buy them. Those little pistons just crumbled.

Any blasting setup would be small for cleaning up odd parts etc. If for nothing else, it would be for the experience and fun tinkering around. Right now I do too much wire wheel work, which is a PITA (especially in the nooks and crannies) and messy. A coworker has a small setup that seems to work very well for him. Not sure what he's using for a compressor, but he mainly etches glass with it and does some minor refinishing.

I would like to get a nice setup for paint. The rattlecan thing got old in a hurry, and I'd prefer to fine tune the mix of what I use. I'm not happy with the downtime and durability I have with spray can paint. Plus, I'd like to tinker with color. It would be good stuff to learn. I'm assuming it would do anything my little Craftsman will do.

Thanks! |

|

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/22/2011 : 10:49:17 Posted - 12/22/2011 : 10:49:17

|

quote:

Originally posted by B112

My sand blaster tells me he uses a screw drive type of compressor. These are big or tow behind units. Lots of air. I have my garage setup with two work spots and have it piped/hosed between the two points. Easier to run a hose in the ceiling than to black pipe it. I too need a bigger compressor.

Yeah, I have no idea what my sandblaster guy has...but it's got to be big. He has several booths, the largest of which is 14x40'. My space is quite small, so I'm limited on what I can use, or do with it. I'd like to simply use my grinder without the wait...that might mean a different compressor, but I'll give this freebie a try and see where it lands me. |

|

|

|

|

olcowhand

USA

5115 Posts |

Posted - 12/22/2011 : 11:34:10 Posted - 12/22/2011 : 11:34:10

|

Duty cycle is mainly the compressor itself, as most compressor motors are rated continuous duty. Those that are not rated at continuous duty won't even state the duty cycle. Those that are rated continuous will state it, as it's a huge selling point. But one rated continuous will cost at least $800, and likely be a 60gl + tank.

DO NOT get an oiless compressor for any more than light general use. They WILL melt down if you exceed their duty cycle.

I've painted many a car & full size tractor with a compressor identical to the one you have! I finally moved up & gave the compressor to my FIL and he still uses it to this day. It's around 35yrs old, maybe 40! |

Daniel in Ky -- So much to do, so little time!

|

Edited by - olcowhand on 12/22/2011 11:35:45 |

|

|

|

midnightpumpkin

USA

888 Posts |

Posted - 12/22/2011 : 11:53:59 Posted - 12/22/2011 : 11:53:59

|

Josh,

I used to have a compressor similar to the one in your picture.

I used to with a pressure pot blaster to completely strip my 56 Ford F-100.

I used the smallest carbide tip I could buy for the blaster. It did the job, to say I ran the Pxxx out of it would be an understatement.

Get it wired up to 220, it will serve you well for a long time.

My siphon feed blast cabinet takes considerably more air than the old pressure pot, I have upgraded to a 5HP vertical tank with a 19 CFM rating. That was my 50th birthday present from my family, it came well after the truck project was done.

John U |

|

|

|

BRAD1975

Canada

1562 Posts |

Posted - 12/22/2011 : 15:47:41 Posted - 12/22/2011 : 15:47:41

|

it might be easier to just find a comparable 3hp motor in a 110v model and swap it out

but 220v is always nice to have for the welder you havent bought yet

|

|

|

|

wlewis379

USA

402 Posts |

Posted - 12/22/2011 : 16:14:03 Posted - 12/22/2011 : 16:14:03

|

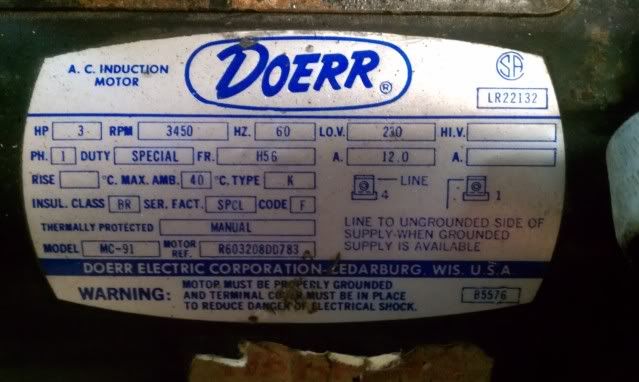

| You want to look at CFM output. I have a 5hp compressor 60 gal tank, running off 220 volts with a cfm output of 18 cfm at 120psi. This will run my paint guns and air tools reasonably well. There are times when I have to leave it catch up like when I'm painting a car or large object. I should change the tip size in the paint gun so it will use less air. Better yet a hvlp paint gun setup would solve the problem. Bottom line is lots of CFM output the more the better. Look at the motor see if you can rewire it for 220 volts. Some motors can be run off 110 or 220 volts look at the wiring diagram on the label or tag. |

Happy Trails Bill

Insert Image:

People who are all wrapped up in themselves are overdressed |

Edited by - wlewis379 on 12/23/2011 01:33:15 |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/22/2011 : 21:17:11 Posted - 12/22/2011 : 21:17:11

|

| This one it wired for 220...it's not a dual stage, so it's 220 or nothin. I've heard a guy is better off with 220 because the amperage can be too high if you're running off 110. Plus, looking at the price of decent 110 and dual stage motors, I'd rather sink the money into copper and the right outlet and breaker. |

|

|

|

|

wlewis379

USA

402 Posts |

Posted - 12/22/2011 : 22:56:41 Posted - 12/22/2011 : 22:56:41

|

quote:

Originally posted by Talntedmrgreen

This one it wired for 220...it's not a dual stage, so it's 220 or nothin. I've heard a guy is better off with 220 because the amperage can be too high if you're running off 110. Plus, looking at the price of decent 110 and dual stage motors, I'd rather sink the money into copper and the right outlet and breaker.

How much is it going to cost to wire it for 220 volt?Its your pocket book. I was not suggesting that you run it on 110 volt forever. I was thinking you could look at the one you have and see if it can be reversed to run on 110 until you can get the 220 wired up, if that's what you are going to do. Yes it will run better on 220 no doubt about it. I have a small compressor like the one you were given that I use outside of the garage, it runs just fine off 110 volts. I also use it with my portable generator. Its good for running a nailer or airing up tires in the yard ect. Maybe you could sell that one and put the money towards a larger compressor because I know your going to want one. I know I did. |

Happy Trails Bill

Insert Image:

People who are all wrapped up in themselves are overdressed |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/23/2011 : 20:58:39 Posted - 12/23/2011 : 20:58:39

|

Oh, I'd love a larger unit...with my current accomodations I just don't have the room, or a real need for a bigger setup. Someday, when we get the polebarn etc, maybe =] (My wife is going to need a change of britches when she sees my plan to convert 'her' small space to a temporary paint booth)

I would LOVE to have a unit to get a start in welding too, and with the free compressor, I don't mind running the 220. I think it will be nice to have out in the garage. I'm looking at about 9' of wire, so I shouldn't be in too bad of shape when it hits the wallet. $60, $70? I have been researching this motor, and I'm not seeing where it has the option to rework to run off 110, otherwise, that could be an option. Motors themselves are real pricey. The buddy who gave it to me is running a similar, 2hp compressor on a 15A/110 line and it trips over and over. He's in the process of looking at running a new dedicated line too.

I'm picking up lots of info...good stuff to learn, thanks! |

|

|

|

|

wlewis379

USA

402 Posts |

Posted - 12/23/2011 : 21:57:09 Posted - 12/23/2011 : 21:57:09

|

I have a 200 amp service in my garage nothing smaller than a 20 amp breaker in the service panel. My best friend and buddy and I did the wiring. He is a certified electrician. We also built the garage. Took us 3 years in our spare time we had to work in between time  . I was looking at the picture of the information on your motor and I don't see any amperage rating so I would not go any lower than 20 amps for a breaker. # 12 wire. . I was looking at the picture of the information on your motor and I don't see any amperage rating so I would not go any lower than 20 amps for a breaker. # 12 wire.

|

Happy Trails Bill

Insert Image:

People who are all wrapped up in themselves are overdressed |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 12/24/2011 : 07:32:43 Posted - 12/24/2011 : 07:32:43

|

Bill, thats simply gorgeous! How I would love to have a space like that....

I was figuring on 20A....I didnt think I would need more, and the oddball Hart-lock plug on this thing is rated to 15A. Im going to switch that over to a more common plug. Took me a bit of investigating to even find out what it was. It's a twist lock style, but more compact than Im used to seeing. |

|

|

|

|

olcowhand

USA

5115 Posts |

Posted - 12/24/2011 : 09:28:27 Posted - 12/24/2011 : 09:28:27

|

| It's a 12 amp motor, so a 15 or 20 amp 220V breaker will do. I'd go 20 amp in case you buy a welder. |

Daniel in Ky -- So much to do, so little time!

|

|

|

|

wlewis379

USA

402 Posts |

Posted - 12/24/2011 : 15:52:20 Posted - 12/24/2011 : 15:52:20

|

quote:

Originally posted by olcowhand

It's a 12 amp motor, so a 15 or 20 amp 220V breaker will do. I'd go 20 amp in case you buy a welder.

Well Daniel that tells me what the A. stands for on the tag I wasn't sure it was for amps or not.( A 12 ) That clears that up. you run your welder off a 20 amp circuit? I use a 50amp on mine. |

Happy Trails Bill

Insert Image:

People who are all wrapped up in themselves are overdressed |

|

|

Topic Topic  |

|