| Author |

Topic Topic  |

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/02/2010 : 09:48:02 Posted - 11/02/2010 : 09:48:02

|

Thanks for the photo! I figured that chain needed to support by attaching somewhere, but did not have the small bracket you have bolted to your frame. I have the perfect piece at home to slap that on.

Richard- While I appreciate the caution, and will heed your advice, my question was concerning how to keep the speed of the mower down. I'm not comfortable with how fast it runs at my slowest idle, let alone half throttle as the manual originally suggests. I want this thing to last, but I also want to use it. My tractor simply wont drive where I need to mow, at anything under half throttle, so I'd like to adjust pulley size to get the rpm of the mower down as low as I can.

Has anyone ever shrunk their PTO pulley from the BGB to slow an attachment? With all the pulleys between my mower and all that HP, I'm thinking I can adjust with reletive ease to run this thing,a nd prevent failure. This baby is my new *jewell*! |

|

Edited by - Talntedmrgreen on 11/02/2010 09:49:04 |

|

|

|

freddie

USA

2129 Posts |

Posted - 11/02/2010 : 10:23:58 Posted - 11/02/2010 : 10:23:58

|

josh, put a ten inch pully on the rear to slow the tractor down, like for tilling. thats the biggest pully you can put on. in first gear you are at a snal crawl.

|

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/02/2010 : 12:01:54 Posted - 11/02/2010 : 12:01:54

|

| No, no...I want to maintain my tractor speed/rpm, while slowing down ONLY the Sickle mower. I would like to move up to a larger pulley on teh tractor, for tilling, but have too many projects going to get into it and figure out a new belt length, etc. |

|

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/02/2010 : 13:20:43 Posted - 11/02/2010 : 13:20:43

|

Skunkhome...found knives. http://www.sickleservice.com/partsDetail.php?item_id=644&sort=&g_offset=&keyword=207-231&category_id=4

Cost is $4.33...I'm assuming that is for the each, and they sell in quantities of 25. I think a set will run ya $110-ish plus shipping. I have yet to call them to confirm. I wouldn't mind replacing all of mine, and hanging onto the originals, but $100+ is a lot of dough.

Not sure if they have rock gaurds yet... |

|

Edited by - Talntedmrgreen on 11/02/2010 13:21:11 |

|

|

|

Richard L.

USA

483 Posts |

Posted - 11/02/2010 : 13:53:33 Posted - 11/02/2010 : 13:53:33

|

| I know it's hard to fathom such a great looking piece of equipment not being able to just rip through and mow anything in it's way at a good clip you'll soon find you'll be unpleasantly surprised. It's not a DR field and brush mower and I think that's what you should invest in to get the most modern equipment to do the job because this is not going to do it for long. To me these mowers are more of a novelty than anything because you cannot expect the mower engine to be turning so slowly because it won't cool well at such low rpm's. Sure, if you're going out to mow 100 feet of brush along the road it won't kill your engine at a slow speed for that amount of time but long processes of mowing at an idle you're taking a huge risk. Also, and this is important, you want to go very slow with these as they will easily clog and start stretching the bar and just a bunch of bad things will happen especially when you know parts aren't readily available. They are not anywhere near as good working as much more modern stuff on the market nowadays. It might work good for a short amount of time mowing fast if you're lucky and not have any bigger obstacles but think about it while you're watching it disintegrate and wonder to yourself. Was there a better method? Don't get me wrong in the right circumstances they'll do an excellent job if you know their limitations and if they're still in halfway decent shape but lots of these have been abused many times and are close to the end of their life before you even got a chance to use it. |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/02/2010 : 15:16:49 Posted - 11/02/2010 : 15:16:49

|

| My application is not going to require I rip through anything. It's more for fun than anything else. However, where I will use the rig, I simply cannot gain forward motion at an idle. It's not going to work. I can't even get out of my back yard without hitting half throttle. My concern is to prevent damage to the mower. It would make a beautiful paper weight, but the fun is in using the thing! =] |

|

|

|

|

simplelife

USA

1385 Posts |

Posted - 11/02/2010 : 17:58:49 Posted - 11/02/2010 : 17:58:49

|

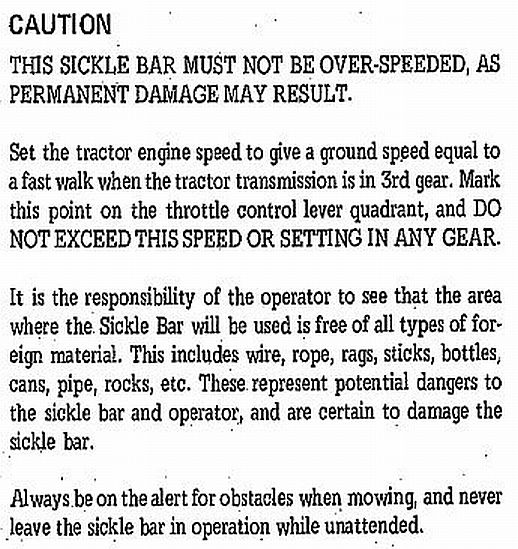

Here is a clip from my owners manual detailing how to determine the speed.

|

|

|

|

skunkhome

USA

12829 Posts |

Posted - 11/02/2010 : 18:57:32 Posted - 11/02/2010 : 18:57:32

|

| Richard, all that you said is true, however you haven't said anything we aren't faced with everyday with these old tractors. Same is true with many antiques. One of the alluring things about them is marveling at how well they work despite their age and the ingenious things we keep coming up with to keep them in the field. |

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/07/2010 : 20:01:36 Posted - 11/07/2010 : 20:01:36

|

| Anyone have a photo of the cable attachment to their sickle? How bout a measurement for the assist-spring? |

|

|

|

|

Talntedmrgreen

USA

4110 Posts |

|

|

ATF

USA

1892 Posts |

Posted - 11/11/2010 : 19:33:03 Posted - 11/11/2010 : 19:33:03

|

| It didn't meet reserve, auction ended |

|

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/11/2010 : 21:22:38 Posted - 11/11/2010 : 21:22:38

|

| Email him! |

|

|

|

|

skunkhome

USA

12829 Posts |

Posted - 11/11/2010 : 22:17:14 Posted - 11/11/2010 : 22:17:14

|

| I hate to see a piece of machinery sitting down on a gravel floor or even on a concrete floor for that matter without being blocked up. I guess that goes back to my old warehousing days....nothing sits directly on the ground or floor. |

Phil

"They that can give up essential liberty to obtain a little temporary safety deserve neither safety nor liberty."

Benjamin Franklin |

|

|

|

Talntedmrgreen

USA

4110 Posts |

Posted - 11/13/2010 : 18:41:59 Posted - 11/13/2010 : 18:41:59

|

| Where I work, its stricly forbidden to have ANYTHING tough the floor. I have homemade rolling carts for all my attachments. Keeps them dry, easy to clean around, and simple to shuffle. When I get my barn, I'll have them on racks! |

|

|

|

Topic Topic  |

|