BGB Repair

Note: This article is draft at this point with the focus of identifying the differences between the BGB (Bevel Gear Box) units used in the various classic Simplicity and Allis Chalmers tractors. Pictures, measurements and various notes will be added as discovered, found and provided. Feel free to work on a discussion on this topic if you're repairing one of these.

Disassembly and Assembly

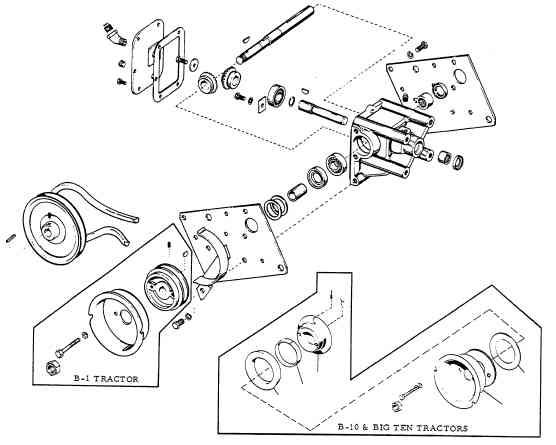

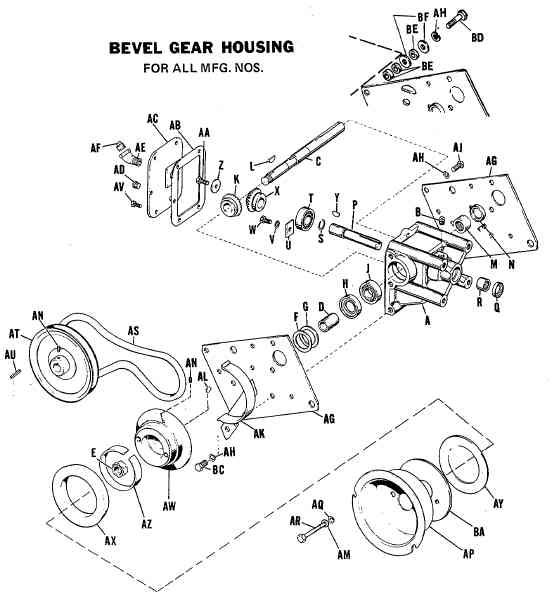

The following is a sketch showing the basic BGB for all models:

Disassemble from tractor as follows:

1. Remove seat assembly.

2. Remove dash assembly.

3. Remove top frame cover.

4. Support tractor under frame just ahead of bevel gear housing.

5. Disconnect brake linkage, clutch-brake rod and transmission shift rod.

6. Remove transmission drive belt and capscrews securing transmission to side plates.

7. Roll transmission rearward from tractor.

8. Disconnect drive shaft.

9. Remove gear shaft flange from bevel gear shaft.

10. Remove capscrews holding bevel gear housing to frame, lift off housing.

11. Remove rope starter pulley.

12. Remove transmission drive pulley.

13. Remove P.T.O. drive pulley.

14. Remove side plate and rear cover.

15. Back up the driven bevel gear and carefully drive the driven shaft to the left until the key is free of gear.

16. Remove key and drive shaft out left side of housing.

17. Remove bearing clamp plate.

18. Drive front shaft, bearing and bevel gear assembly out of housing.

19. Remove bevel gear retaining capscrew and washer.

20. Remove bevel gear and bearing from shaft.

21. Inspect bearing and seal, renew if necessary.

Installation is reverse of removal.

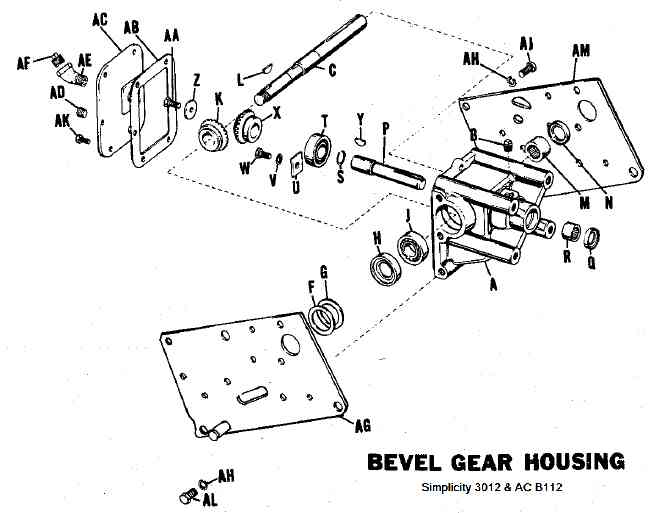

Simplicity 3012 and AC B112 BGB Parts Breakdown

The following is a sketch of the BGB from an Allis Chalmers B112 or a Simplicity 3012. Note that the shaft (part C) is longer than the other models of classic tractors to support the Variable Speed Drive.

Some example pricing as of 6/4/2007 is as follows:

C - SHAFT 0 875 DIA 13 0 $65.80

K - GEAR BEVEL 2 10OD 0 $61.61

M - BEARING NEEDLE 0 875 $5.75

P - SHAFT 0 7869DIA 4 8 $50.38

J,T - BEARING BALL 20MM ID $8.15 or 230029 SPINDLE BEARING $7.33

(Specs: ID: .787" OD: 1.850" Height: .551" )

X - GEAR BEVEL 2 10OD 0 $53.77

Simplicity 3112H BEVEL GEAR HOUSING

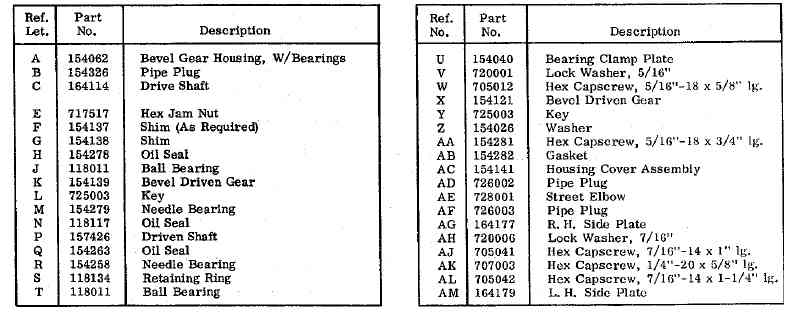

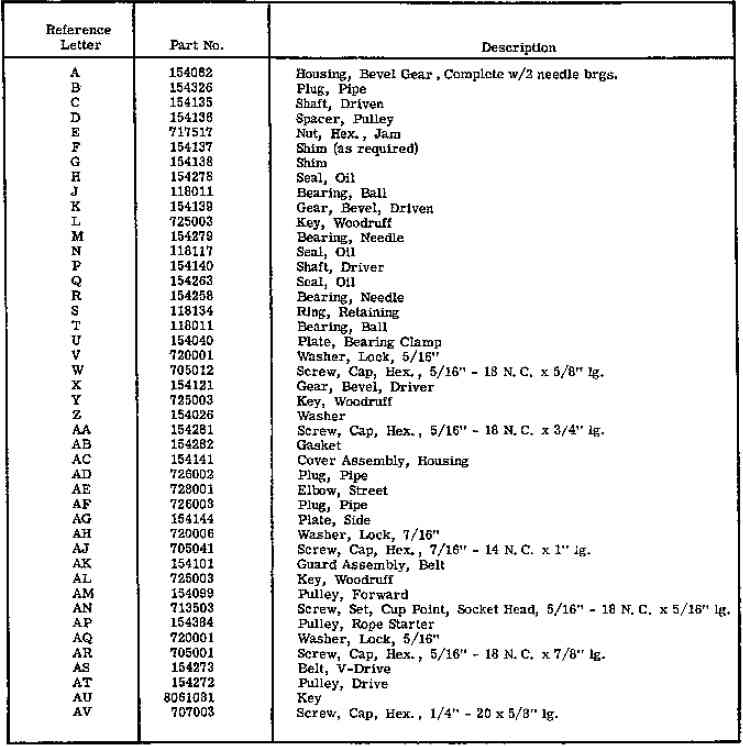

A 154062 Bevel Gear Housing, W/Bearings

B 154326 NLA-FITTING-PIPE

C 2154135SM Drive Shaft

E 2717517 Hex Jam Nut

F 2154137SM Shim (As Required) 0 005 THK 1 375

G 2154138SM Shim 0 0478THK 1 375

H 2157669SM Oil Seal

J 2118011SM Ball Bearing

K 2154139SM Bevel Driven Gear

L 2725003 Key

M 2154279SM Needle Bearing

N 2118117SM Oil Seal

P 2157426SM Driven Shaft

Q 1612093SM Oil Seal

R 2154258SM Needle Bearing

S 2118134SM Retaining Ring

T 2118011SM Ball Bearing

U 2154040SM Bearing Clamp Plate

V 2720001 Lock Washer. 5/16"

W 2705012 Hex Capscrew, 5/16"-18 x 5/8" lg.

X 2154121SM Bevel Driven Gear

Y 2725003 Key

Z 2154026 Washer

AA 2154281 Hex Capscrew, 5/16"-18 x 3/4" lg.

AB 2154282SM Gasket

AC 164249 NLA-COVER-HOUSIN

AD 2726002 Pipe Plug

AE 2728501 Street Elbow

AF 2726003 Pipe Plug

AG 166049 NLA-PLATE,SIDE R

AH 2720006 Lock Washer, 7/16"

AJ 2705041 Hex Cap Screw, 7/16"-14 x 1" lg.

AK 2707003 Hex Cap Screw, 1/4"-20 x 5/8" lg.

AL 2705042 Hex Capscrew, 7/16"-14 x 1-1/4" lg.

AM 166054 NLA-SIDE PLATE-L

AP 166077 NLA-SPACER-0.752

AQ 2717022 Full Hex Nut, 7/16"-14

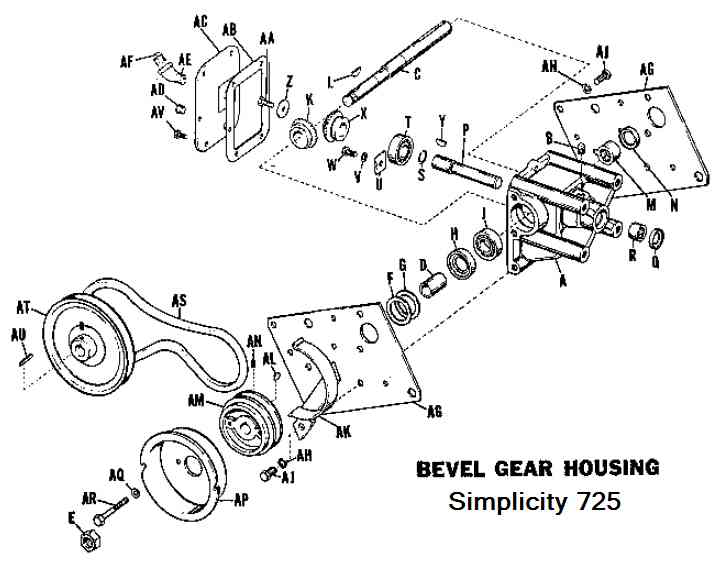

Simplicity 725 BGB Parts Breakdown

The following is a sketch of the BGB from the Simplicity 725.

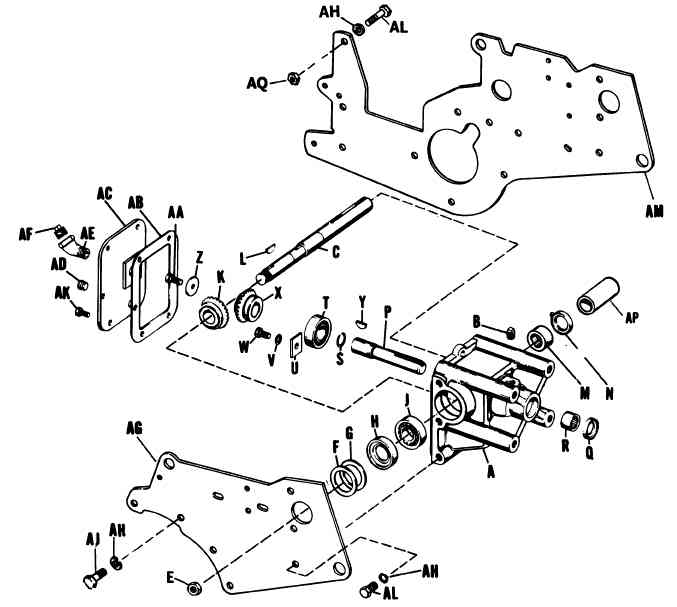

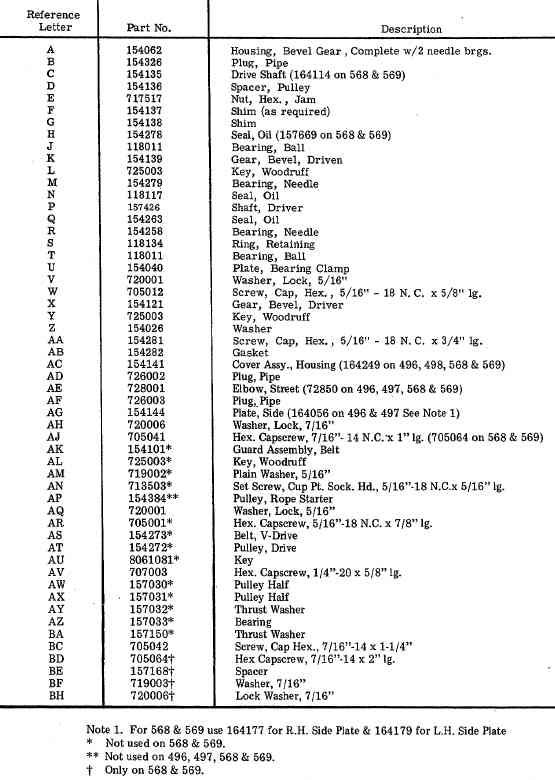

All Landlord Models BGB Parts Breakdown

The following is a sketch of the BGB for all the Landlord models.

Note: The 496 & 497 codes are for the 2210 tractors and 568 & 569 are for the 3210 Tractors. For part letters; C, H, AC, AE, AG, and AJ these are all different for these tractors.

Comparison of the 3012/B112 BGB to the 725 BGB

The following is a list of the part number different between the B112/3012 and the 725 tractors:

1. Shaft - part C 164114 / 154135

2. Spacer - part D NA / 154136

3. Driver - part P 157426 / 154140

Parts after AG are pulley and the outer plates specific to the various tractor models. Notice that the B112/3012 the left and right plates (AG/AM) are different verse on the 725 the plates are the same (AG) on both sides.

TIPS

Removal of the Drive Shaft Flange is easier if you use 3/8"-16 x 3" bolts to push yoke off. Turn each screw a turn on each side until the flange comes off. Easier than using a puller.

In the photo below, I've used 3/8"-16 x 2" bolts and a couple of pieces of steel for spacers because I didn't have 3/8"-16 x 3" bolts. You will need a 5/16" alan wrench, a 9/16" wrench for the bolts. Some things to have in your tractor kit.

articles for reference:

http://www.michaelstractors.com/forum/topic.asp?TOPIC_ID=4486 |