| T O P I C R E V I E W |

| Tclark |

Posted - 01/15/2013 : 23:00:13

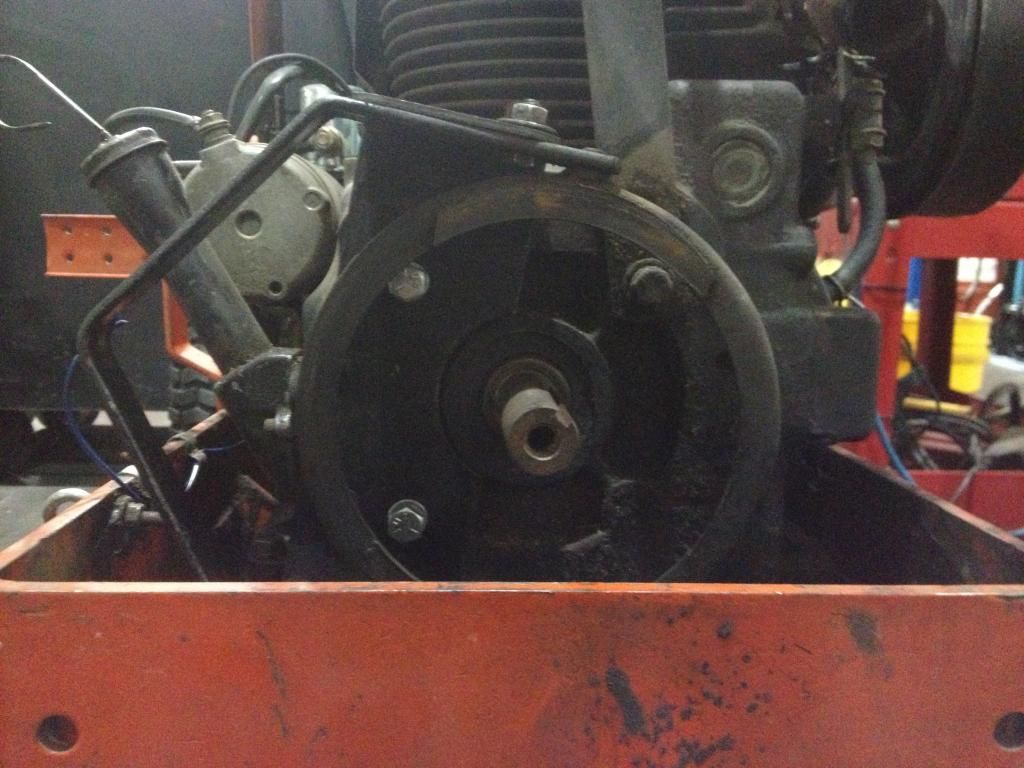

(pics were requested)I recieved my new to me front pto for my 712 in the mail yesterday and here is my hang up for not having it done already.

#1 I dont think it is supposed to be mounted like it is being tilted. i believe it is supposed to be 100 percent vertical.this is the only way it bolts up using the original holes.

#2 I used the supplied spacer that that the diagram says goes on before anything else.

which leads me to #3, With the supplied spacer in place and all mocked up the pivot point maxs out and the pulley doesnt even contact the drive part or clutch disk (if you will).

so my question is i shoul i drill new holes to first off mount it 100 percent vertical and also new hole to move the pivot point back or should i add spacers behind the "clutch disk/plate" to make up for the extra space? |

| 9 L A T E S T R E P L I E S (Newest First) |

| skunkhome |

Posted - 01/17/2013 : 22:12:48

If it doesn't hang up on the frame, starter or rub the belt in that position it should work just fine... The clutch plates don't know that it is cocked. |

| acdad |

Posted - 01/17/2013 : 17:31:28

I use a B series snowblower on my 914H but use a non electric front pto. |

| Homesteader |

Posted - 01/17/2013 : 07:45:41

I would think it would need to be straight up and down, but I don't know for sure. Check for a clear path for clutch rod and operation of the clutch fork. |

| Tclark |

Posted - 01/16/2013 : 18:13:35

Thank you much now do I need to make it straight up and down or is it okay angled like that |

| Homesteader |

Posted - 01/16/2013 : 16:13:31

3/4" from the center of the pivot hole, that yours already has, to the center of the hole that you need to drill.

|

| Tclark |

Posted - 01/16/2013 : 15:57:01

Greg are you measuring the pivot point holes and Is your measurement from the outer set of holes or is it from the block side of the bracket to the first set of holes I need the measurement for the Kohler holer

|

| Homesteader |

Posted - 01/16/2013 : 15:07:21

The front PTO that you have was for the earlier tractors with Briggs engines. I believe that the only real difference in the later one, that was also for tractors with single cylinder Kohler engines up to 16hp, was that the mounting bracket had two sets of holes for mounting the clutch fork. The best that I can measure while mine is on the tractor, is that the second set of holes are 3/4", center to center, behind the outer set.

Here's a manual showing the bracket:

http://bsintek.basco.com/BriggsDocumentDisplay/default.aspx?filename=jgEBGP_etN1tG5EPa7mRgtLvBCd6

|

| Tclark |

Posted - 01/16/2013 : 08:46:05

The centers are lined up so all good on that part

|

| skunkhome |

Posted - 01/15/2013 : 23:53:59

Is it concentric with the shaft? |