| T O P I C R E V I E W |

| larry8200 |

Posted - 02/20/2011 : 13:57:19

Some of you expressed an interest in this winch from a previous post, so here it is.

This is a light duty winch for occasional use only. A winch to do serious work would need to be mounted to the rear frame, have relays or solenoids controlled by a toggle switch, 8 to 4 gauge wire... a whole different ballpark. That being said, this has been a great addition to my Sovereign and cost less than $300 8 years ago.

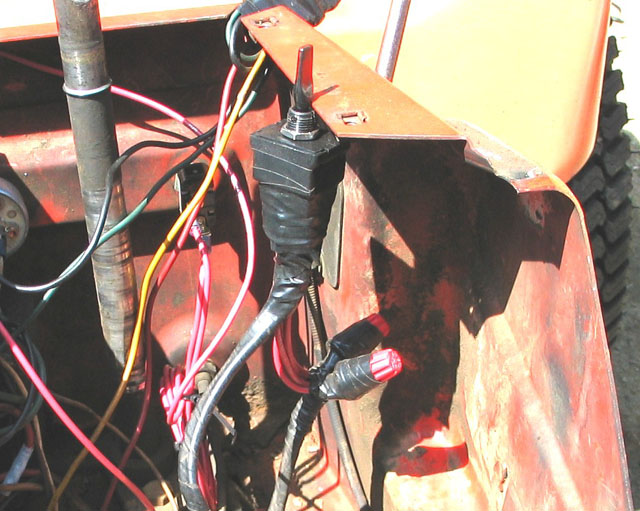

To start with, I wanted it mounted such that it would not interfere with the rear lift kit, (not on in pictures)that meant mounting it on the back of the fender wich is neither strong enough or large enough for even this small winch. I cut a piece of 1/2" X 6" bar stock to the length of the mounting area of the winch, and attached it with 2 3/8 stove bolts countersunk flush with the surface of the barstock, Then bolted the winch to that. I also replaced the original hinge bolts on the fender with grade 5's.

The winch mounting plate could easily be welded to the crossbar on the fender frame, but this has been plenty strong, I've pulled 300 plus pound rocks, medium tree's and the back of the tractor off the ground. I also like the option of being able to easily remove or modify the setup.

The wiring was a lttle trickier...

The original wiring had provision for a 20 amp draw for accessories regulated by a 20 amp automatic resetting circuit breaker. The Lights draw 20 amps, and the electric lift kit draws 20 plus amps. Raising the snow thrower packed with wet snow would trip it, as well as raising any implements while the lights were on.

I eliminated the original power wire and circuit breaker and replaced it with a 30 amp inline fuse mounted under the hood. At the same time I ran a second dedicated 30 amp circuit for the winch.

I then ran 2 12 gauge automotive primary wire wrapped in tape from the dash to the winch. With the electric lift kit that was fun. I then drilled a 1/2" hole in the dash for the toggle switch. I could not get all the 12 gauge wires on the switch, so I had to use wirenuts (boo!) to split the + and - wires into pairs. This enabled me to have only 1 wire on each of the switches terminals, though.

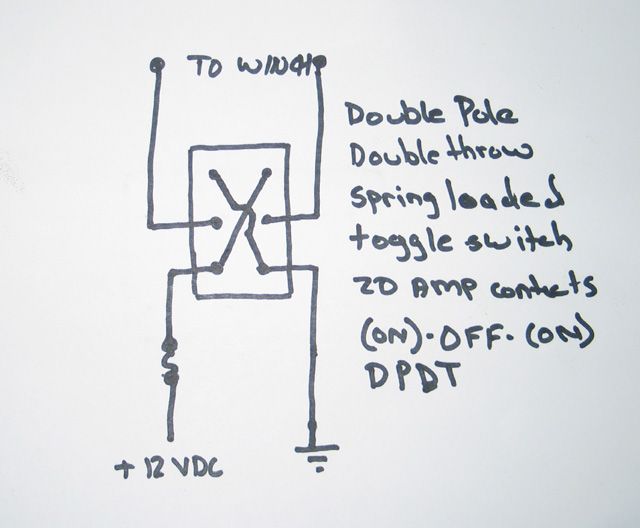

Forgive the artwork... this schematic shows how to wire the DPDT (on)-off-(on) Toggle. That's a Double Pole, Double throw 3 position switch with momentary (spring loaded) contacts.

I replaced (before using) the 5/16 galvanized steel cable the winch came with, with 40' of 3/16 stainless steel wire rope. Rpaced the hook with a sling hook with latch. The reason for the wire rope: 1) it's stronger. 2) The galvy is nasty. 3) A winch only developes it's rated pull when the cable is winding the bare drum. As the drum fills with cable and it's diamater increases, you can lose as much as 75% of it's pulling power. The wire rope allowed me more cable and a smaller maximum drum size at the same time.

You will need:

Winch

Steel Plate

20' 12 gauge primary wire

Electrical tape

DPDT momentary toggle wth 20 amp contacts

Inline fuse holder

fuses

3/8 flat head bolts

other bolts as required

butt splices and ring terminals

wire ties

in addition to common tools a 3/4 or 1" countersink and way to cut plate (I used a sawzall)

Have a great day

Larry

|

| 4 L A T E S T R E P L I E S (Newest First) |

| larry8200 |

Posted - 02/23/2011 : 08:27:26

quote:

Originally posted by ASEguy

Does you generator keep up with the winch? Gerard

A good 51-R battery will run it for probably an hour before draining it to where it wont start the engine. I 'd thought that it might blow the 30 amp fuse I have on it pulling hard, but it doesn't. Best guess is it draws 20-25 amps, and the S/G charges at 15 amps so if you ran it long enough it would drain the battery. I suspect if you attempted to use it more than 5-10 minuites at a time the winch motor would burn out long before the battery became an issue.

I use it 5 minuites here, 5 minuites there and it's never been a problem |

| ASEguy |

Posted - 02/23/2011 : 07:07:51

Larry, That is a really nice idea and a good looking set-up you have there. I'd like one mounted on a quick disconnect type of mount like a reciever hitch. Does you generator keep up with the winch? Gerard |

| larry8200 |

Posted - 02/21/2011 : 09:06:02

It would be worth it. |

| simplelife |

Posted - 02/20/2011 : 21:05:48

Nice job on the winch mount.

I have a reversing 12v winch that we use on the big trailer. It is mounted to a receiver bar and we slide it into a receiver bracket we built into the front trailer frame. I have often thought about building a receiver mount that I can affix to the back or front of the tractor similar to the front/rear ball hitches. Then we could use the same winch in any of the locations. |

|

|