| T O P I C R E V I E W |

| Falky |

Posted - 01/05/2011 : 11:52:41

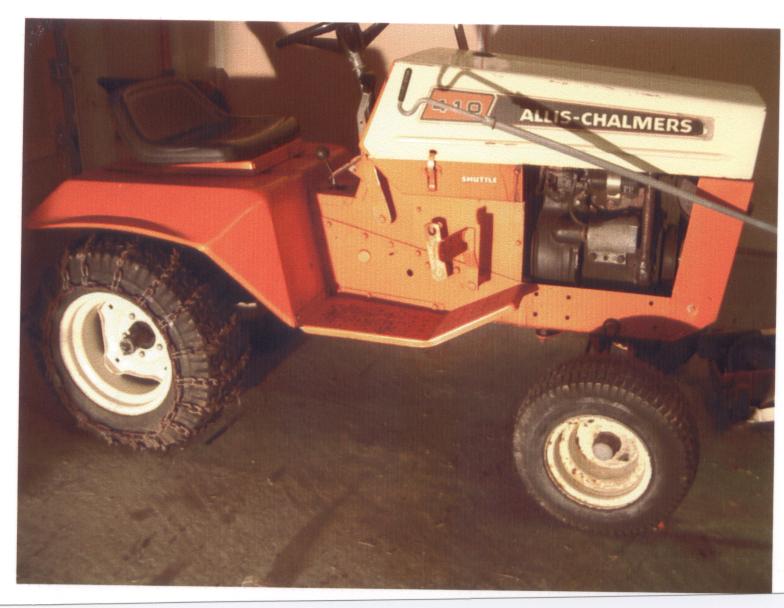

Hi guys Happy New Year I was out blowing the adjacent driveways with the 410 and lost reverse. The tractor has all gears going forward but nothing in reverse. I checked the reverse belt and it seems ok Its too cold to go clambering around on a concrete floor . Does any body have any suggesations that might eleminate a lot of time for me. Thanks. David.

Insert Image:  |

| 15 L A T E S T R E P L I E S (Newest First) |

| sammiefish |

Posted - 01/23/2011 : 08:02:43

thats great to hear!!!

Im glad you got it going...

sounds like it was a pretty easy fix for you.

great thread |

| Falky |

Posted - 01/17/2011 : 19:51:45

to-day received friction material and drilled and counter sunk all 7 holes pop riveted the material to the brake band and photographed it but can't reduce the picture to the required size for MT. WARNING wear gloves when drilling this material or counter sinking. I did'nt and have experienced the discomfort from those little pieces of wire woven into the product. After final assembly took the tractor out with the snow blower and moved a good foot and a half of previously blown snow along the drive I'm tickled to pieces with the performance of a 16 HP motor. |

| sammiefish |

Posted - 01/13/2011 : 16:50:00

that is interesting... I didnt understand when you first mentioned it

my 416S planetary wobbles a bit as well... Ill be looking into this

|

| Falky |

Posted - 01/13/2011 : 12:43:41

yesterday got my 1/2 inch socket set back from a neighbour and used the 1 1/8 socket to remove the nut holding the planetary carrier on. I wanted to find out why it wobbled. The flange bearing is worn ever so slightly but enough over the 6 inch diameter to make it appear worse than it is. I will grease this and put it back on. My friction material should be here tomorrow or Monday so can reassemble using 3/16 aluminum pop rivets. drill the holes first then counter sink enough to bury the heads of the pop rivets. Being aluminum if it wears down again (NOT) it won't scratch the drum shoe. Thanks for your help gents. |

| oldsarge |

Posted - 01/10/2011 : 18:18:49

quote:

Originally posted by skunkhome

I would use contact cement! If you use an epoxy you need to use something that stays flexible and won't crack when the band is drawn tight. Btw: that band is available but considerably more than $10.

Yeah,you're right, I never thought about the flexing, but if it's riveted,get sme rivets from hdwe store and re-rivet but if it's riveted,get sme rivets from hdwe store and re-rivet |

| skunkhome |

Posted - 01/10/2011 : 17:30:52

I would use contact cement! If you use an epoxy you need to use something that stays flexible and won't crack when the band is drawn tight. Btw: that band is available but considerably more than $10. |

| Falky |

Posted - 01/10/2011 : 15:34:47

That should have read $10 including shipping. I will have to remove the 7 brass rivets then clean it up. What epoxy do you suggest using.? |

| oldsarge |

Posted - 01/10/2011 : 14:40:27

quote:

Originally posted by Falky

I have just got off of the phone with Phoenix Friction Material in Woodbridge Ontario and have ordered a piece of material 3/4 X 14 X 3/16 $10 plus shipping.

That oughta do it! Come on Epoxy.Wire wheel on a bench grinder should get the remainder of the lining off. |

| Falky |

Posted - 01/10/2011 : 11:28:23

I have just got off of the phone with Phoenix Friction Material in Woodbridge Ontario and have ordered a piece of material 3/4 X 14 X 3/16 $10 plus shipping. |

| Falky |

Posted - 01/08/2011 : 11:27:03

Good morning guys this morning I pulled the cotter pin and found that there was no more adjustment on the rod to tighten the shoe. I removed the shoe and found that it has been previously brazed together, not a problem, however I did find that the shoe material is about one third gone (wore out) bare metal. Question can the shoe still be purchased new? if so where? if not can the shoe material be purchased and replaced. Can I get a second hand shoe? Is it normal for the brake drum to be a little loose? |

| Richard L. |

Posted - 01/07/2011 : 11:23:18

Not sure if this would apply or not but I once picked up a tractor that wouldn't move from sitting quite awhile and other obvious concerns. Turned out somebody had adusted/bent the clutch idler pulley set-up for the drive and in the process created a sticking point to not allow the idler spring to put tension back on the the idler pulley movement. I was able to grasp the drive pulleys and wiggle them ever so much where the spring took over and brought them back into tension. After a little lubrication and liberal bending of the idler backet it sprang back into as good as new. This sometimes is a cause of many of the problems with the drive if somebody gets monkeyng around with pry bars and an idea!! First thing is to check and see if you've got full clutch pedal movement and all pulleys are moving as intended. |

| Falky |

Posted - 01/07/2011 : 09:32:23

Thank you guys specially oldsarge I did check the brake drum with the machine running in gear and reverse and the drum still turns. So I think this will be an easy fix this time. I am glad for this site. I sent olcowhand a PM for the side hood decals for a 416 Allis Chalmers and not heard from him, I guess milking is taking up all of his spare time. Any way thank you all once again David. |

| skunkhome |

Posted - 01/05/2011 : 21:15:51

The belt you call the reverse belt is actually the forward clutch belt. (There is no reverse belt)If it will go forward in all gears the problem is not a belt. If it fails to reverse then one of two things are amiss. The brake band on the planetary hub is worn out or out of adjustment or the planetary hub is shot. Look at your planetary hub while it is in reverse. It should be stationary. If it is still turning then the brake is faulty. If it is stationary and it still isn,t moving in reverse then the hub is shot and needs to be repaired or replaced. Check out chapter nine on the link below. It has a very detailed description of the shuttle operation. Once you understand the principle it is easy to trouble shoot.

|

| oldsarge |

Posted - 01/05/2011 : 19:35:37

Perform the adjustments before you take it Apart!!They need the levers and brakes adjusted every so often.Mine's been blowing snow here for 30 yrs.The brake band on the outside of the assembly MUST stop the drum for reverse to work!!!!!!! |

| Falky |

Posted - 01/05/2011 : 18:38:55

Thank you I'll take pictures as I'm disassembling it and then we will both know. I think the diagrams will be very useful. thanks again. David |