| T O P I C R E V I E W |

| Roy |

Posted - 05/20/2008 : 21:59:32

The PTO pulley on my 3212V had the keyway wallowed out so to salvage the pulley I cut a new keyway then drilled and tapped new set screw threads for it. I don't have a broach set so I used my lathe with a boring bar and manually moved the carriage to take 0.005" per cut to make the 3/16" x 0.09375" deep keyway.

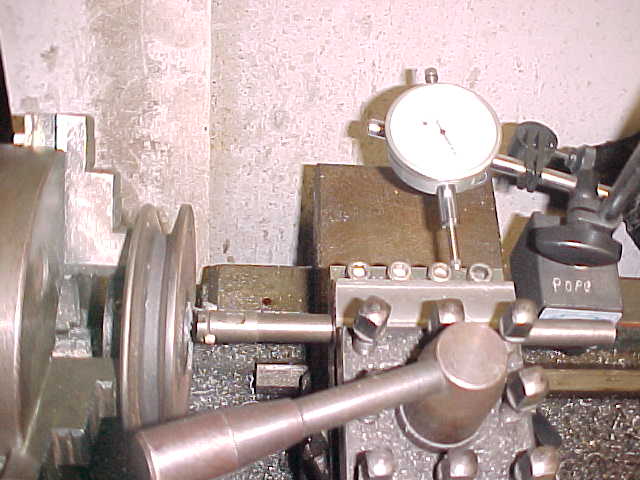

Lathe setup:

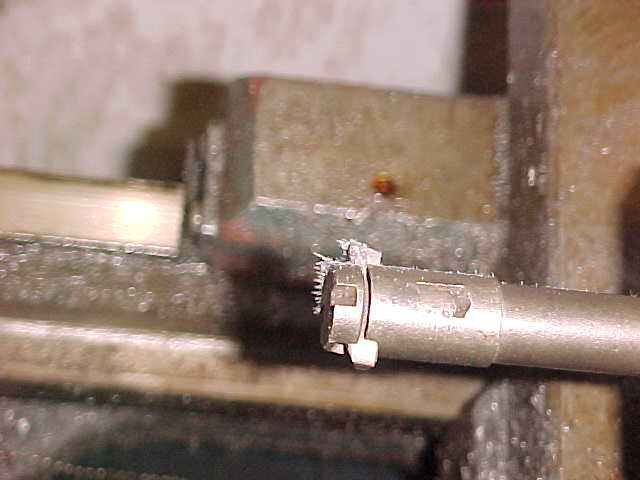

Boring bar and bit:

Pulley with new keyway partially cut:

Bad keyway:

New keyway:

Complete with set screw:

My cutter bit was 0.005" too narrow so I had to hand file 0.0025" from each side to make the key would fit but overall the job came out good for a first time learning experience.  |

| 5 L A T E S T R E P L I E S (Newest First) |

| Roy |

Posted - 05/21/2008 : 21:32:36

Jac,

"Do any of you do work like that for fellow members?"

I made four sets of Mackissic chipper/shredder hitches and clutch pulley assemblies for Ambler at Simple Tractors. Traded them to him for a chipper/shredder.

So, guess the answer is, yes, sometimes.  |

| jac |

Posted - 05/21/2008 : 16:15:08

Do any of you do work like that for fellow members? |

| Roy |

Posted - 05/21/2008 : 15:46:59

Daniel,

Easiest would be your method first and finish the corners with my method.  |

| olcowhand |

Posted - 05/21/2008 : 09:31:33

Not thought of doing it that way. I use a milling bit the right width, bore down & make a half-round key slot, then finish the corners with a file. I'll try that way the next time & see which works easier. |

| skunkhome |

Posted - 05/20/2008 : 23:26:36

Good Save, Roy. Another skill I should have learned when I was a pup. |